Rocket Lab reaches 500 Rutherford engine test fires

Huntington Beach, California and Auckland, New Zealand January 31, 2018:

Rocket Lab, a US aerospace company with operations in New Zealand, has this month completed its 500th test fire of the orbital-class Rutherford rocket engine.

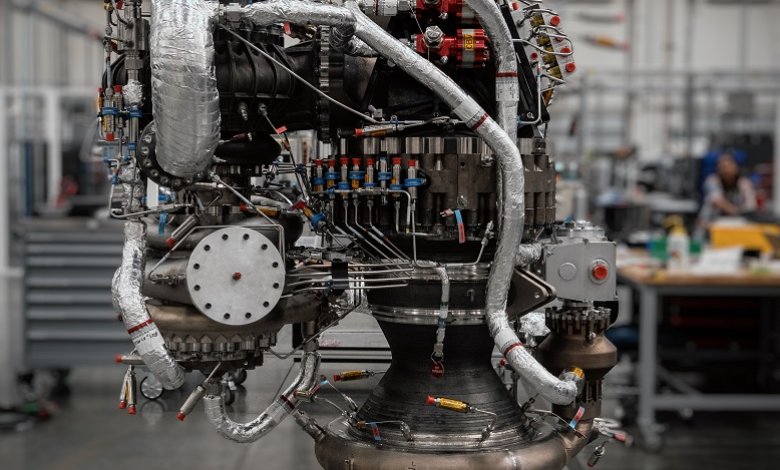

Designed and manufactured in-house by Rocket Lab, development of the 3D printed, electric turbo-pump fed Rutherford engine began in 2013, with the first test fire taking place in December of the same year. The engines attained flight heritage during Rocket Lab’s first test flight in May 2017.

The 500th Rutherford test fire burned for a duration of 100 seconds. The milestone firing brings the Rutherford engine series to 19,000 seconds (more than 300 minutes) of cumulative firing time since the first hot fire test in December 2013.

“The Rutherford engine was designed from the beginning to be both high performing and fast to manufacture on a mass scale,” said Lachlan Matchett, Vice President of Propulsion. “By enabling faster, scalable engine production we speed up production of the whole vehicle. We can print an entire engine in as little as 24 hours. This allows us to build and launch at unprecedented frequencies to democratize access to space, enabling the creation of crucial orbital infrastructure.”

Rocket Lab has produced a total of 40 flight-ready engines to date, and aims to produce another 100 engines by the end of this year. The Rutherford engine’s production scalability is facilitated by additive manufacturing, or 3D printed, primary components. With a 3D printed combustion chamber, injectors, pumps, and main propellant valves, Rutherford has the most 3D printed components of any rocket engine in the world.

The in-house design also features the use of electrically driven propellant pumps, rather than turbomachinery, further reducing complexity and build-time. This unique approach allows unmatched precision and control of propellent flow and a significant increase in performance through mass savings.

About the Rutherford engine:

Weighing just 35 kg each, nine Rutherford engines propel Rocket Lab’s Electron launch vehicle to space powered by a fuel mixture of highly refined kerosene and liquid oxygen. Rutherford uses an entirely new propulsion cycle to create outstanding efficiency for a kerosene-oxygen engine.

Rutherford is used as both a first stage and as a second stage engine, with sea level versions on Electron’s first stage producing 24 kN (5,500 lbf) of thrust and has a specific impulse of 311 s (3.05 km/s), while the vacuum optimized version operating on Electron’s second stage produces a max thrust of 24 kN (5,500 lbf) of thrust and has a specific impulse of 343 s (3.36 km/s).

The Rutherford engine is named after New Zealand physicist Ernest Rutherford, a Nobel laureate famous for his work in discovering radioactive half-life and being the first to split the atom.

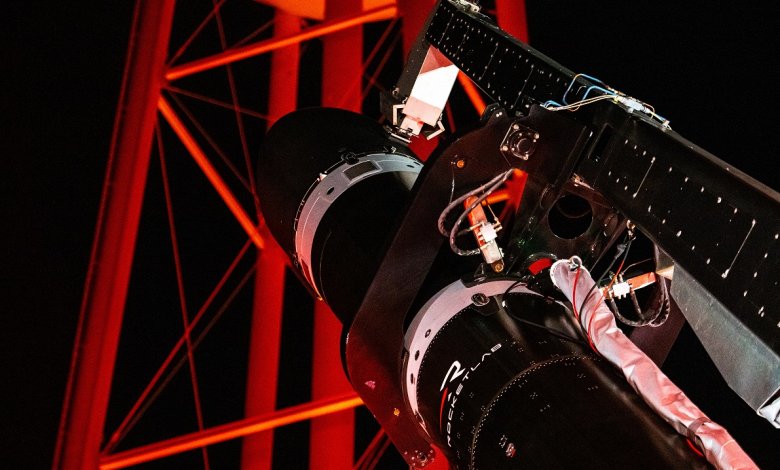

Rutherford engines are manufactured at Rocket Lab’s headquarters in California, USA, and shipped to Auckland, New Zealand for testing before integration with the Electron launch vehicle and eventual launch from Rocket Lab’s own orbital launch facility, Launch Complex-1, on the Māhia peninsula.