Electron

Dedicated access to space for small satellites

56 launches

to date

to date

203 satellites

successfully

deployed

successfully

deployed

Only reusable-capable small

launch vehicle

launch vehicle

3 dedicated

launch pads

launch pads

Your mission, your way

Tailored orbits, schedule control, responsive launch

Overview

- Height

- 18 m / 59 ft

- Diameter

- 1.2 m / 3.9 ft

- Stages

- 2 + Kick Stage

- Wet Mass

- 13,000 kg / 28,660 lb

- Payload to LEO

- 300 kg / 661 lb

- Structure

- Carbon Composite

- Propellant

- LOX / Kerosene

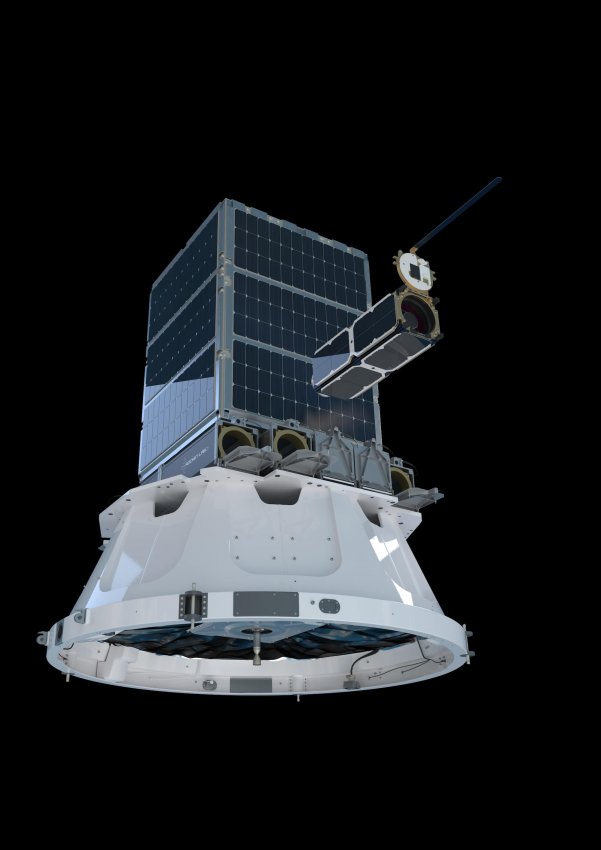

Kick Stage

Electron’s unique Kick Stage is designed to deliver small satellites to precise and unique orbits, whether flying as dedicated or rideshare.

- Deployment of payloads at multiple planes/inclinations

- Higher altitude deployment

- Hosted payload support

- Multiple trajectory changes

- Sustained low altitude orbits

- Deorbiting payloads to eliminate space debris

Rutherford Engine

Proven performance. The world’s first 3D-printed, electric-pump-fed rocket engine.

First Stage

- 9 Sea-level Rutherford Engines

- Lift-off Thrust: 190 kN (43,000 lbf)

- Peak Thrust: 224 kN (50,600 lbf)

- ISP: 311 seconds

Second Stage

- Single Vacuum Rutherford Engine

- Total Thrust: 25.8 kN (5,800 lbf)

- ISP: 343 seconds

Reusability

Electron is the only reusable orbital-class small rocket. Capturing and reflying Electron’s first stage enables higher launch frequency without expanding production and lowers launch costs.